Engineering applied to the world motor museum: Motorwold

The Motorworld complex is an engineering differential where the how and the why define every technical decision we make.

One of the biggest challenges we face was the implementation of the high-capacity electrical system. The magnitude of this task is reflected in figures that speak for themselves:

- Deployment of 35 coils of 300 mm².totaling more than 40 kilometers of cable

- 105 300 mm² aluminum cables to connect the main switchboard to the transfer switchboard located next to the transformer substation.

- Implementation of a capacitor bank which has significantly reduced the complex's reactive energy consumption.

This electrical infrastructure is not only a technical feat, but also the backbone that gives life to the entire complex, guaranteeing optimal operation even under conditions of maximum demand.

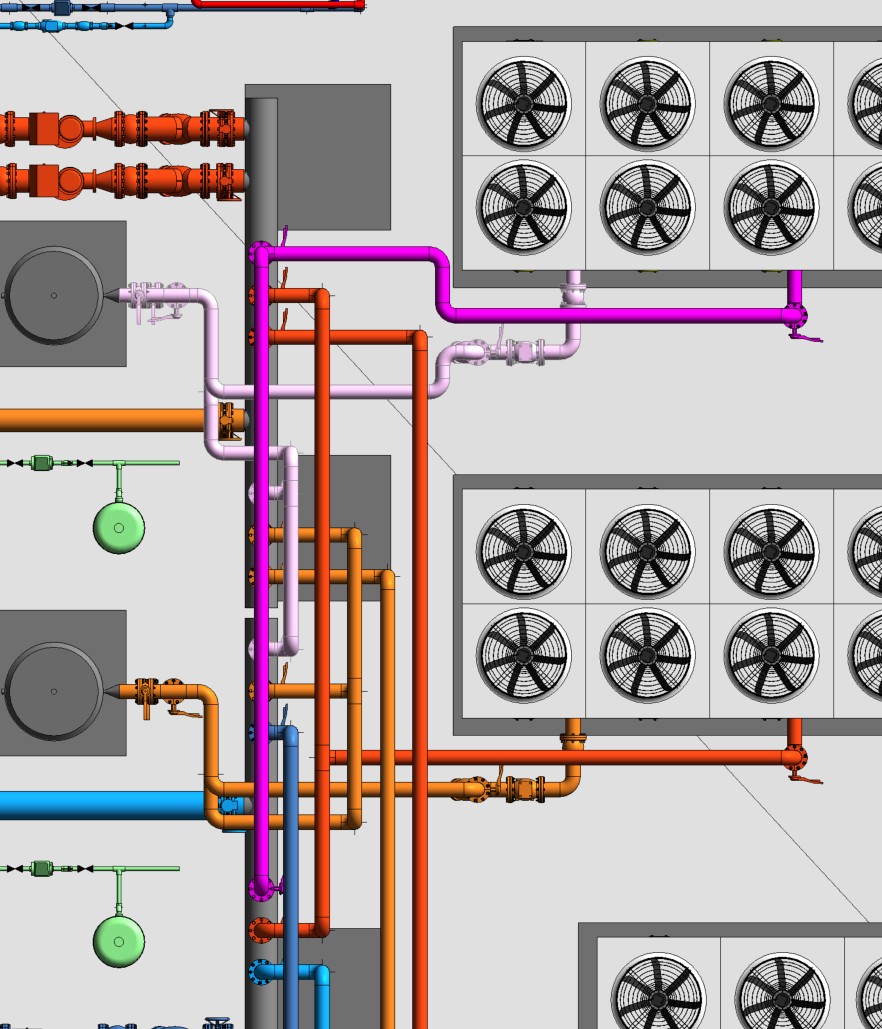

Air-conditioning and DHW systems: sustainable engineering

Our vision of engineering transcends mere functionality to embrace sustainability as a guiding principle. Therefore, we develop and implement:

Environmentally conscious air conditioning

- Natural refrigerant R290 for DHW production machines, reaching temperatures of 70-75°C with minimum energy consumption.

- R32 gas system for general air-conditioning, with a GWP (Atmospheric Warming Potential) of 150

- Ventilation installation with heat recovery units that maximize the use of the thermal energy of existing air

Energy efficiency by design

- Premium thermal insulation in all hydraulic pipelines, minimizing energy losses

- Air conditioners with freecooling technology that take advantage of the favorable conditions of the outside air

- 200-8″ general weather piping diameter that optimize the flow

The results translate into power figures managed with maximum efficiency:

- Thermal power: 673.8 KW (cooling) and 787.6 KW (heating)

- Total electrical power: 1600 KW

- Cold battery power: 314.882 KW

- Heating coil power: 131,918 KW

Operational intelligence: advanced monitoring and control

For Talat, 21st century engineering must be smart, connected and proactive. That is why we implement:

- Strategically located counters y network analyzers on all subframes of the complex, allowing real-time management of the electrical consumption

- Open integration of KNX devices on the platform EcoStruxure Building Operation from Schneider Electric

- Synoptic system for AHUs that provides real-time visualization of all critical parameters

This control ecosystem makes it possible not only to maintain optimal comfort, but also to generate up to 30% energy savings and a substantial reduction in operating costs.

Excellence in execution: the value of time

At Talat we understand that engineering excellence is not only measured by technical quality, but also by the ability to meet deadlines. Motorworld's comprehensive project was completed in a record time of 8 months.

The Talat differential: engineering with purpose

What sets Talat apart in the industry is not only the what we dobut how and why we do it. Our holistic approach integrates:

- Sustainability as a non-negotiable principleby implementing solutions that reduce carbon footprint

- Energy efficiency by designnot as a later addition

- Long-term visionwith facilities prepared for future challenges

- Commitment to technical excellence in each component and system

Results that last

Talat's intervention in Motorworld has made it possible to create a complex that stands out for:

- Maximum energy efficiency thanks to intelligent management systems

- Minimal environmental impact through the use of sustainable technologies

- Operational flexibility that can be adapted to different conditions of use

- Significant reduction in operating costs in the medium and long term

Do you want to know how Talat's differential engineering can transform your project?

Contact our team of specialists.